Moulded pulp packaging has become an essential solution for businesses seeking eco-friendly, cost-effective, and durable packaging options. Whether you’re packaging electronics, food, or other consumer goods, selecting the right moulded pulp packaging can make a significant difference in your product’s protection, sustainability, and customer satisfaction. This article will guide you through the critical considerations to ensure you choose the best moulded pulp packaging for your business.

Understand the Types of Moulded Pulp Packaging

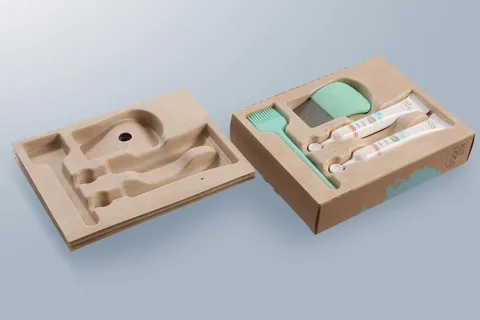

Before choosing moulded pulp packaging, it’s important to understand the different types available. Moulded pulp is generally categorized into four main types: thick wall, transfer, thermoformed, and processed. Thick wall moulded pulp is sturdy and ideal for heavy-duty applications, such as automotive parts. Transfer moulded pulp, on the other hand, is lightweight and commonly used for egg trays and cup carriers. Thermoformed moulded pulp offers a smoother surface, making it suitable for premium packaging, such as electronics or cosmetic products. Processed moulded pulp undergoes additional treatments like printing or coatings for enhanced functionality.

Each type of moulded pulp has distinct characteristics and applications. Your choice will depend on your product’s weight, fragility, and aesthetic requirements. For instance, if your product demands superior visual appeal, thermoformed moulded pulp might be the best option. Conversely, if you need a more cost-effective solution for bulk transport, transfer moulded pulp could be the ideal choice.

Evaluate the Environmental Benefits

One of the main advantages of moulded pulp packaging is its eco-friendliness. Made from recycled paper, cardboard, or agricultural waste, moulded pulp is biodegradable, recyclable, and compostable. When selecting packaging for your business, consider how the sustainability of moulded pulp aligns with your corporate responsibility goals and customer expectations.

Moreover, choosing moulded pulp packaging can enhance your brand image by demonstrating a commitment to environmental preservation. Customers today prefer brands that prioritize sustainability. By opting for moulded pulp, you not only reduce your environmental footprint but also attract eco-conscious consumers, giving your business a competitive edge.

Assess Product Protection and Functionality

While sustainability is crucial, the primary purpose of packaging is to protect your products. Moulded pulp packaging is known for its excellent shock absorption and cushioning properties, making it suitable for a wide range of products. To choose the best packaging, evaluate your product’s specific needs, such as fragility, weight, and dimensions.

For example, if your product is fragile or requires precise positioning, consider custom moulded pulp designs. Many manufacturers offer tailored solutions, ensuring that the packaging fits your product perfectly. Additionally, assess whether the moulded pulp packaging can handle external factors such as moisture or temperature changes, depending on your product’s storage and transportation conditions.

Consider Cost-Effectiveness and Scalability

Cost is a critical factor when selecting any packaging solution. Moulded pulp is generally cost-effective due to its reliance on recycled materials and efficient manufacturing processes. However, it’s essential to consider the total cost, including design, production, and logistics.

Scalability is another aspect to evaluate. If your business requires large-scale production, ensure that your supplier can meet your demand consistently without compromising quality. Many moulded pulp manufacturers offer bulk production discounts, which can further reduce costs. Additionally, consider the long-term savings from reduced product damage during transit and lower disposal costs due to the packaging’s recyclability.

Partner with a Reliable Supplier

Finally, the quality of your moulded pulp packaging heavily depends on the supplier you choose. Look for a supplier with a proven track record of delivering high-quality moulded pulp packaging. Check their certifications, manufacturing capabilities, and commitment to sustainability.

Additionally, consider suppliers who offer customization services. A good supplier will work closely with you to design moulded pulp packaging that meets your specific requirements. Don’t hesitate to request samples and test the packaging before committing to a bulk order. By partnering with a reliable supplier, you ensure that your packaging aligns with your business goals and enhances your overall product offering.

Conclusion

Choosing the best moulded pulp packaging for your business involves understanding the different types, prioritizing environmental benefits, ensuring product protection, evaluating cost-effectiveness, and partnering with a trusted supplier. By considering these factors, you can make an informed decision that supports your business’s operational efficiency and sustainability goals. As the demand for eco-friendly packaging solutions continues to grow, investing in high-quality moulded pulp packaging is a step toward a greener and more prosperous future for your business.